Brand new Sheeters - from roll(s) to seets in finished fotmat (slitting and sheeting in 1 machine)

Brand new Sheeters - from roll(s) to seets in finished fotmat (slitting and sheeting in 1 machine)

Location:Italy

Description

This series of sheeters features an innovative production system that directly converts reels (single or double) into finished products.

The product size can be customized according to customer requirements, eliminating the need for a separate slitter rewinder.

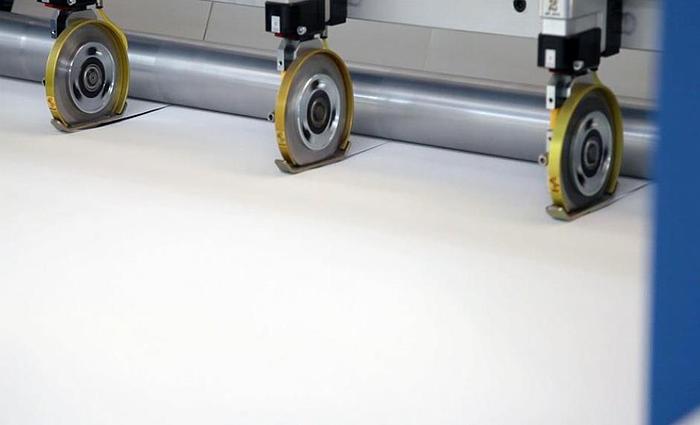

By simultaneously cutting two paper reels with double register control, this system combines functions that traditionally required separate machines, such as a cross cutter and a linear cutter. This approach boosts production speed (up to 500 cuts per minute), reduces operator requirements, and lowers the cost of the finished product.

The unwinders are equipped with a braking system that maintains consistent tension on the reels during acceleration, deceleration, and diameter variations. This line uses vertical blades to divide reels into up to 5 parts, with the option to add more blades for side trimming.

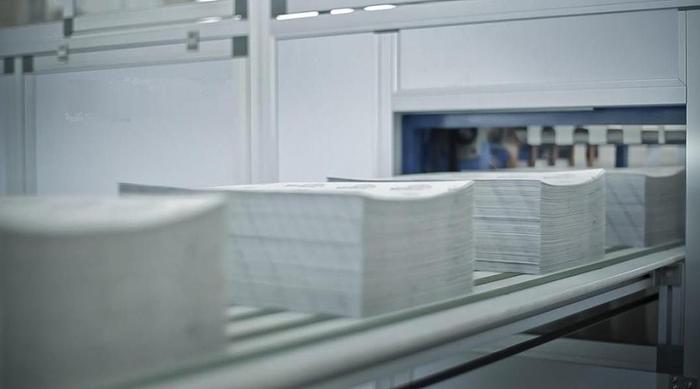

Stepper motors in the cutting assembly allow for automatic paper size adjustments. The system can achieve high cutting speeds (up to 500 cuts/min.) and handles a wide range of materials, including tissue paper, wrapping paper, gift paper, coupled paper, PE, PET, BOPP, etc. (14-100 g/sm). Conveyor belts carry the sheets to the stacker system, which features an automatic ream-changing mechanism.

The selected number of sheets (50-1000) can be transferred from the conveyor belts to boxes or trays and then moved to an automatic packing system (shrink-wrapping, taping, labeling, and palletizing).

The machine is operated via a 10.4” color touchscreen control panel, mounted on a rotating aluminum arm. Operators can manually set work parameters, access production data, save previous programs, and perform diagnostics, maintenance, and repair tasks. The system's automation also integrates with a web-based diagnostic platform, allowing for remote monitoring and control.

Specifications

| Manufacturer | Brand new |

| Model | Sheeters - from roll(s) to seets in finished fotmat (Made in Italy) |

| Condition | New |

| Material | Tissue paper, Wrapping and gift paper, Coupled paper, PE, PET, BOPP etc. (14-60 g/sm) |

| Reel max. width | 1000 mm or 1200 mm (depending on the configuration/model) |

| Max. weight of the reel | 1000 kg or 1100 kg (depending on the configuration/model) |

| Core reel diameter | 70 mm or 76 mm |

| Max. std reel diameter | 1050 mm |

| Min. cutting width | 250 mm or 300 mm (depending on the configuration/model) |

| Max. cutting width | 500 mm or 600 mm (depending on the configuration/model) |

| Min. cut lenght | 200 mm |

| Max. cut lenght | 400 mm |

| Cut Accuracy | +/- 0,2 |

| Max. Speed | 500 cuts/min (depending on material and format) |

| Max. electric power | 15 kW |

| Noise emission | < 70 db(A) |

| Additional information | Safety stop devices - Aluminium and lexan antiaccident security guards - Air generation system - Triple efficiency antistatic bars - Motorized reel unwinders - Double register control - Automatic joggers with 3 linear slides - Automatic ream unloading system |

| Optional (on request) | Electric hoist with stand - 10-strip cutting system - Double motorized decurling system - Automatic shrink-wrap packaging unit |